More than ever, we are all responsible for making our possible contribution to environmental protection! The possibilities for this are given by various measures and can often be implemented very attractively for companies from an economic point of view.

Since its foundation, ONI has been developing and building system solutions with which you as a plastics processor can optimize your energy costs and processes in the production environment. By using this technology, our customers make a significant contribution to environmental protection! The ONI plants and systems installed at our customers worldwide reduce the emission of climate-damaging CO2 by approx. 5,900,000,000 kg per year!

Energy management systems have made it clear to many plastics processors what high energy-saving potential there is in the field of plastics processing! Lifting them is often amazingly simple and extremely lucrative, because the savings measures are self-financed in a very short time and donated subsidies from the state are added!

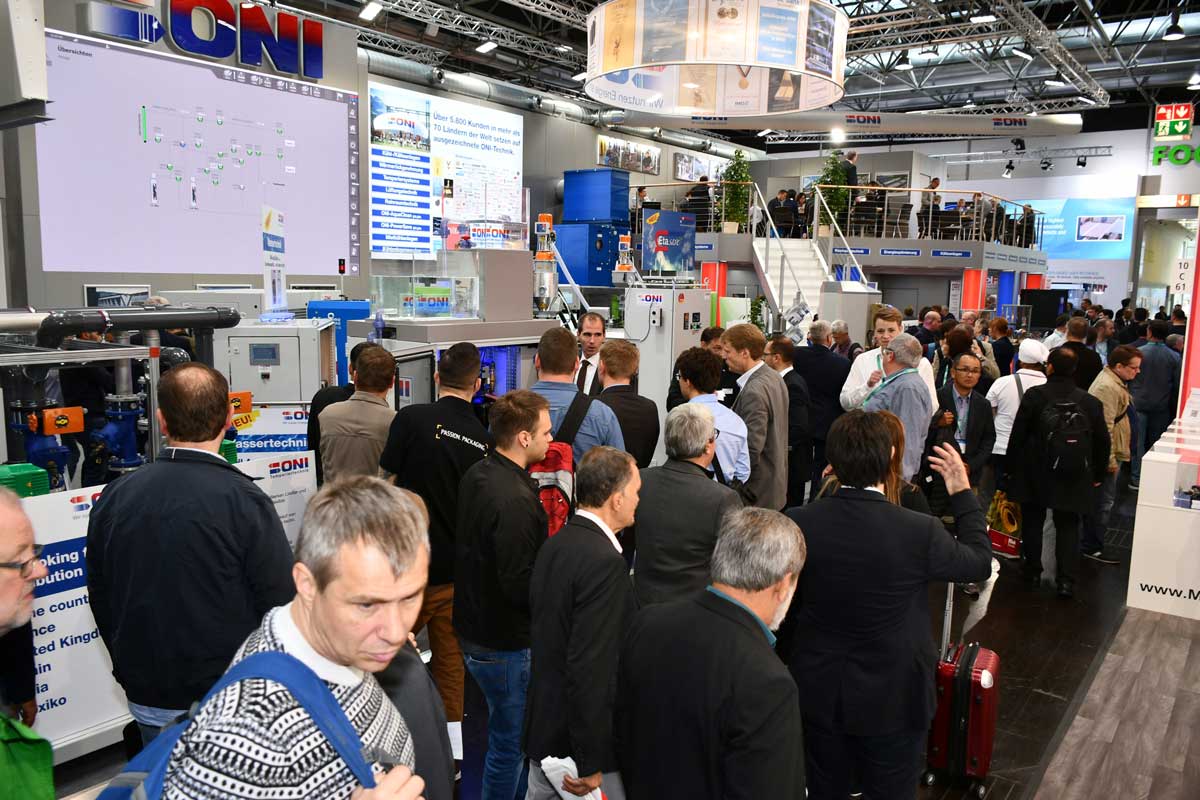

The K trade fair went much better for us than expected. After 8 trade fair days, we have almost the same number of trade fair contacts as compared to K-Messe 2016. However, the number of visitors has increased considerably. In concrete terms, more interested experts visited us per company than in 2016. It is pleasing to note that despite a noticeable slowdown, especially in the automotive and packaging sectors, the number of project enquiries regarding energy and process optimisation has risen. One possible reason for this is the subsidies made available by the German government for energy optimization measures and our

Service to make these funding pools usable for our customers and interested parties in connection with project elaborations. In addition, the demand for energy-saving systems that are self-financing in a short period of time and consequently lead to considerable CO2 reductions in the company is also increasing. The great interest shown by visitors to the fair in new and further developments in these areas is particularly pleasing:

Cooling water treatment with the ONI-AquaClean system technology Here, contaminated water from a tank was fed via an ONI-AquaClean system and returned to a second tank after two filter stages with pre-filter and ultra-fine filter as well as throughput of an ozonation stage, crystal clear and free of bacteria. The practical advantages for the plastics processor when using this system technology range from considerably reduced costs for mould management as well as the use of chemicals and the return of cycle times to originally calculated values.

ONI-PowerSave energy-saving circuit for free cooler supply pumps

Here, a practical example was used to show how using a speed-controlled pump in conjunction with ONI PowerSave system technology can reduce the electricity costs for pump operation of the recooling circuit by 35 % and more. We have simply copied from nature and use physical relationships to massively reduce power consumption in recooling circuits that are equipped with idle free coolers.

In concrete terms, the ONI PowerSave energy-saving circuit consists of additionally installed, hydraulically active components and speed control for the free cooler circuit pump used. The result is convincing. If, for example, a pump with a power requirement of 10.5 kW is used as a basis, this is reduced by approx. 3 kW or 28.5 % to 7.5 kW in full load operation and by up to 65 % in partial load operation after activation of the energy-saving circuit. Taking into account 6,000 operating hours with an average relief of 35%, 22,050 kWh of electricity and more than 11,800 kg of CO2 are saved per year!

New generation of temperature control units and further developed multi-circuit temperature control systems

New series of efficient, powerful and reliable temperature control units, the newly designed and built RHY-T90 series of M and L high performance temperature control units as well as the RHY-High-T160 high temperature version. The advantages at a glance:

- PLC with 7-inch touch display (IP54)

- Heating capacities from 6 to 72 kW

- Cooling capacities from 6 to 480 kW

- Delivery pressure from 6 to 12 bar

- all analog and digital interfaces (e.g. OPC-UA EUROMAP 82.1, Profinet, Profibus)

- Continuously welded stainless steel piping with stainless steel components

- Quick-release fasteners for optimum accessibility during maintenance work

- Ventilation gills instead of conventional ventilation openings

- highly efficient, energy-saving and multi-stage high-performance centrifugal pumps with optional frequency control

- Flow rates up to 35 m3/h

- fully automatic venting

- high-tempered long-life direct heating elements with extremely low surface load of less than 10 W/cm2