Plastic and

metalworking

ONI´s solutions improve company´s competitiveness by reducing their environmental impact and energy costs.

Automobile -

industry

ONI´s customers profit economically and ecologically from ONI´s energy-saving centric optimization of system technology.

Chemical and

food industry

ONI´s products benefit in their development and optimization from decades of experience in energy supply and process technology.

Medical -

technology

ONI´s employees are available as specialized teams providing sustainable development, dynamic growth and full service operations - from consulting to plant construction.

OUR VISION

To reduce energy

costs efficiently and

sustainably!

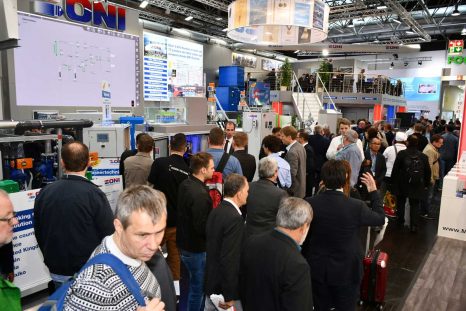

Make use of our experience and our system technology for your success! More than 6,000 industrial customers in over 70 countries around the world rely on our energy-saving systems and use our optimization know-how to sustainably reduce their energy consumption!

Wolfgang Oehm | Managing Partner

JOB OFFERS

One look

into your future!

Discover your possibilities at ONI.

At ONI, you are given the chance to learn, grow and share your success with others on a daily basis. Seize your opportunity: Take the next step together with us.

ONI

energy-saving technology

Energy-saving and process-optimizing

System solutions for industry

◎ Cooling systems

◎ Modular energy centers

◎ Combined heat and power unit (CHP)

◎ Rental cooling systems

◎ Air conditioning & ventilation systems

◎ Compact chillers

◎ Cleanroom technology

◎ Maintenance & service

◎ ONI-AquaClean

◎ Heat recovery

◎ Compressed air systems

◎ EtaControl ®

◎ ONI-PowerSave

◎ Analysis and planning

◎ DC cooling

◎ Rhytemper ®

CUSTOMER FEEDBACK

Consulting,

Execution & Service

Your "team" did a really great job at our factory. I was also fascinated by the trouble-free commissioning and error-free programming of the whole system. It is still running to our complete satisfaction today. Many thanks to all of you for your great work.

Andreas Ernst | Roth Kunststoff AG

We are very pleased to have chosen an ONI system and look forward to continuing this excellent cooperation. There are still a few projects to be done at our company and we are happy to have ONI as a partner at our side.

Melanie Lehmann | Oskar Lehmann GmbH & Co. KG

For more than 20 years, ONI has been responsible for the installation and technical support of refrigeration technology at Hilti Kunststofftechnik GmbH. During this period, we have had only positive experiences, not just in the consultation and the execution quality, but also the technical service.

Bernhard Gell | Project management | HILTI

Energy optimizer:

HOT AIR

-

ONI customers save as much heating energy as the residents of a city like Ludwigshafen or Osnabrück consume annually.

HIGH VOLTAGE

-

In terms of electricity, the savings of all ONI customers corresponds to the annual electricity consumption of all Berlin private households combined!

BREATHE DEEPLY

-

Thanks to new systems technology, ONI customers are helping to reduce emissions in line with Germany's overall climate target.